Trending searches

Popular products

Cart ($0)

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

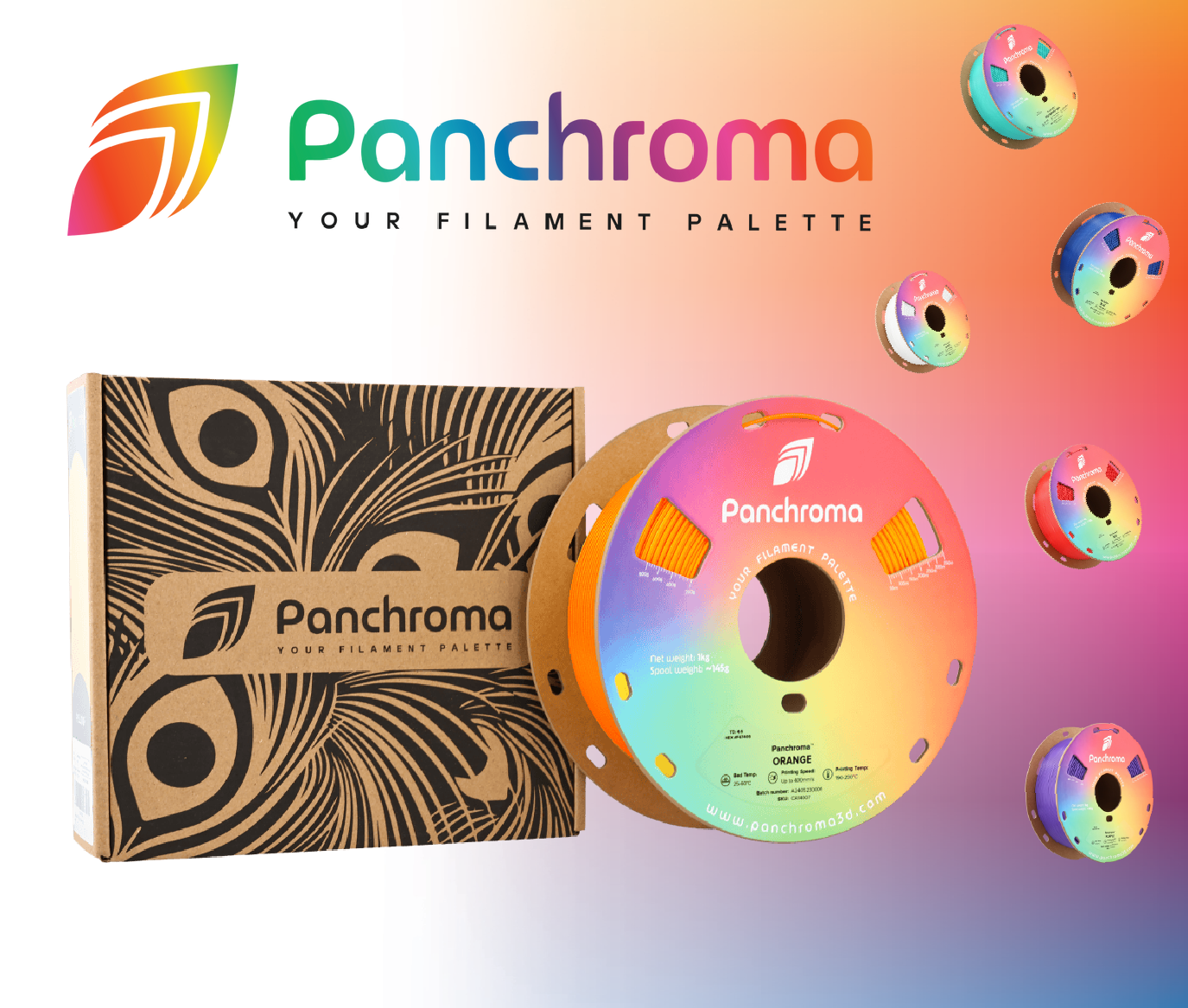

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Want detail in your prints, try resin 3d printing for that fine detail.

Quality brands you can trust

Stock held in New Zealand unless stated for Pre order

NOTE: These are 5-6 days delivery from the US directly at this stage as production is released.

Behold the Mosquito™ Liquid - it uses the same patented technology found in the standard, air-cooled Mosquito™ hotend, but optimized for liquid cooling in heated enclosures.

Like all of our hotends, Mosquito™ Liquid is completely Made in the USA, out of top end materials. The liquid cooling block is precision machined out of a super conductive copper alloy, and coated with a non-marring, highly inert, gold-colored plating that allows for use with any commercially available coolant. Liquid also features our latest Bimetallic Heat Break™ - the first version to be totally conductively cooled. The hotend is available with or without liquid fittings.

Mosquito™ Liquid optimized for printing high temperature plastics such as PPSU, PEEK and PEKK and all general filaments.

Superior heat break performance - conduct 85% less heat than a standard threaded heat break

Increased structural rigidity

450°C temperature rating covers all printable thermoplastics

Modular/adaptable to almost any FFF/FDM printer

Ideal for multi-extrusion systems

Lightweight

Please NOTE:

Shipping lead times are indented, please allow 6 days from order due to demands and stock levels for this product.

Kit Includes:

Includes:

- Mosquito™ Base Liquid (x1)

- Hot Block Hardware (x1)

- Mosquito™ Heat Break - Conduction (x1)

- Mosquito™ Hot Block (x1)

Notes:

- Comes Fully Assembled

- Lead times should be expected. Orders will be assembled and fulfilled in the order in which they are received.

Needed to buy:

We highly recommend the use of thermal paste with the Mosquito™ to provide good thermal conductivity between the hotend and heater/thermistor.

Downloadable 3D models of the Mosquito Hotend are now available on our Documentation page.

Seasoned hobbyists, innovators, and creators take it in stride when they’re struck with a vision of what they could build. Especially when they know that with The Mosquito Hotend™, their 3D printer can deliver the highest resolution and take on engineering-grade plastics that other desktop printers can’t come close to. With minimal layer lines and extreme precision, your vision is about to become reality. A beautiful reality.

By engineering-grade plastics, we’re talking printing at temperatures up to 450 °C. That means you can print car parts, medical devices, and whatever else you can dream up, and you don’t have to buy an over-sized (and overpriced) printer to do the job.

How did Slice Eng accomplish this?

By re-imagining how a hotend is designed and structured from the ground up. The materials in each part of The Mosquito Hotend™ have been hand selected to perform a specific task to optimize your printer’s performance with three goals in mind: lightning speed, beautiful resolution, and increased durability.

The Mosquito Hotend™ is adaptable to virtually any printer, so by swapping one component, you gain the high performance benefits of a printer worth thousands more. Since The Mosquito Hotend™ (designed for beauty) and Mosquito Magnum™ (designed for speed) are the same length, any combination of these hotends can be mounted to one carriage. So you can switch between high-flow and high-precision in the same print.

Oh yeah, and you can change the nozzle with one hand.

Are you ready to see your vision fully realized?

The Mosquito Hotend™ is only available for 1.75 mm filament at this time.

ADDITIONAL DETAILS:

Superior heat break performance

- The heat break conducts 85% less heat into the heat sink than a typical threaded heat break

- Steep temperature gradient at the heat break, and high tolerances along the filament path allow for better transmission of fine motor movements, resulting in beautiful, higher resolution prints

- Steep temperature gradient at the heat break reduces the likelihood of jamming

- Reduced heat transmission removes the need for a large heat sink

- Composite construction of the bimetallic heat break™ allows for the use of materials optimized for heat transfer in each section of the heat break

- Allows for hotend to be mounted with a printed, plastic adapter, without raising safety concerns

Increased structural rigidity

- The heat break has been separated from the structural components of the hotend, allowing for a heat break that is not load bearing, and can be very thin walled. This allows for a reliable, rigid exterior structure

- No components are prone to loosening at the mounting points

- Nozzles can be changed with one hand, without grasping the hot block

- In the case of a severe crash, an entirely new hotend is not necessary, parts can be easily swapped out

Larger temperature operating range

- Specially-engineered high temperature copper alloy in the hot block will not soften at high temperatures in excess of 550C.

- Threads in the hot block will not deform at high temps, allowing removal of nozzles even after multiple high temp heat cycles

- Nickel plating on the hot block reduces radiative heat loss and prevents galling of threads

Modular/adaptable to almost any FFF/FDM printer

- Compact, flat, ambidextrous form factor

- 5 different hole mounting patterns to allow for adaptation to virtually any printer

- Printable adapters can be created to diversify mounting options

Ideal for multiple extrusion systems

- Small form factor and light mass allows for back-to-back mounting with small nozzle-nozzle distance

Lightweight

- Small mass allows for more rapid motion

- Less reinforcement needed for the motors, belts, and drives in the motion system

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!