Trending searches

Popular products

Cart ($0)

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

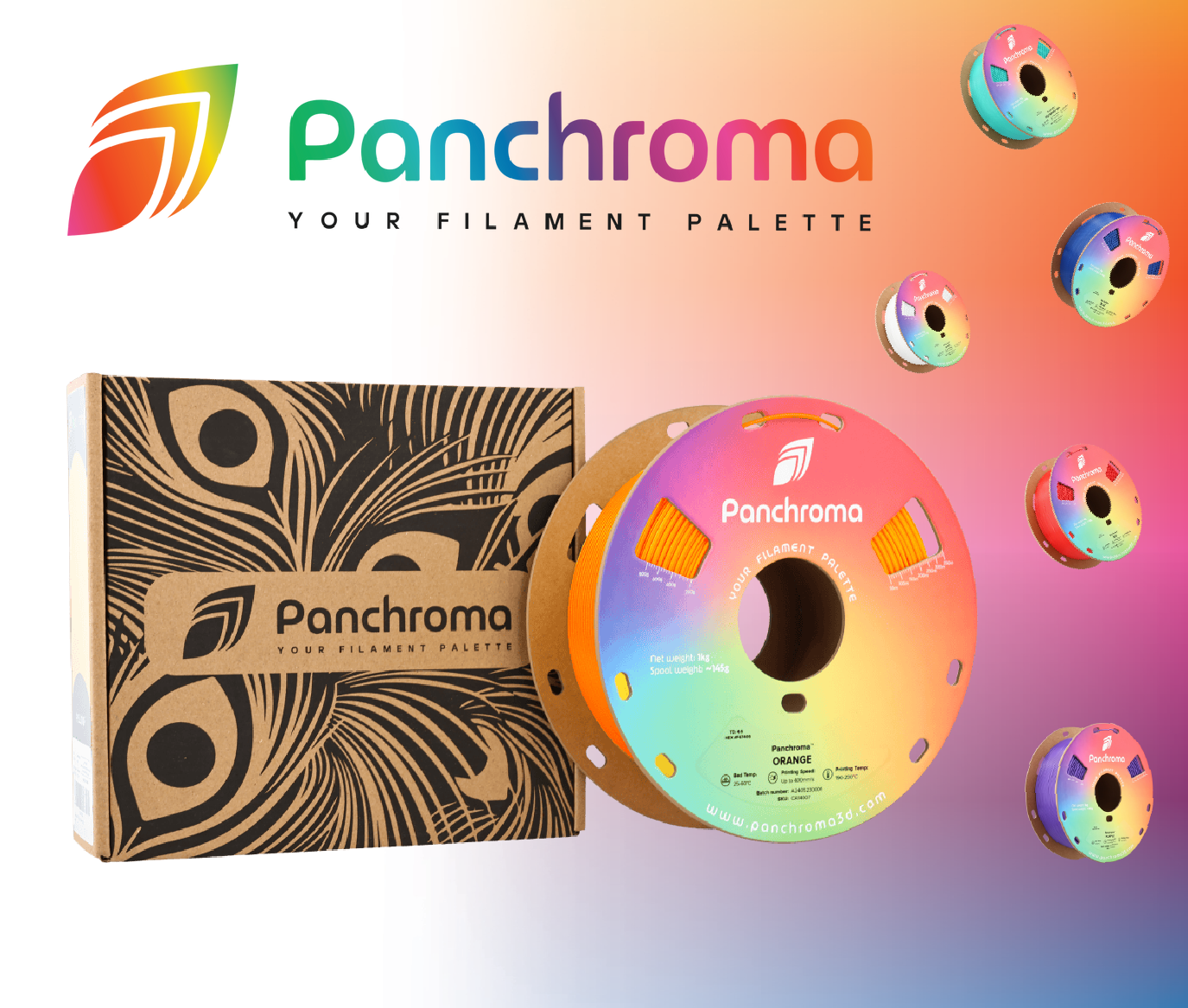

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Want detail in your prints, try resin 3d printing for that fine detail.

Quality brands you can trust

![OBSIDIAN PA6+CF [MARKFORGED ONYX ALTERNATIVE] 1Kg 1.75mm rolls](http://www.formtech.co.nz/cdn/shop/products/Obsidian-CFNylon175mm-Black-1kg-ReelPic.png?v=1645152297&width=1600)

![OBSIDIAN PA6+CF [MARKFORGED ONYX ALTERNATIVE] 1Kg 1.75mm rolls](http://www.formtech.co.nz/cdn/shop/products/Black-Diesel-Part-w-Wireframe-1.png?v=1645152297&width=1600)

![OBSIDIAN PA6+CF [MARKFORGED ONYX ALTERNATIVE] 1Kg 1.75mm rolls](http://www.formtech.co.nz/cdn/shop/products/Generic-Carbon-Fiber-w-ThermHousing.png?v=1645152298&width=1600)

Usually ready in 1 hour

Obsidian™ PA6+CF filament was formulated to be a lower-cost drop-in Markforged Onyx

1kg of Obsidian vs 750g Markforged Onyx

Alternative to ONYX suitable for all Markforged printers and DIY machines.

Alternative to ONYX suitable for all Markforged printers and DIY machines.

IMPORTANT: 3DXTech recommend to dry this filament on 1st use as it can be very hydroscopic even if new.

We developed this material after extensive analysis and testing on our own in-house Markforged printer and many outside beta testers.

The result is a seamless printing experience that produces parts with an outstanding appearance and excellent mechanical properties.

Made using premium high-modulus carbon fiber and PA6 copolymer, Obsidian™ is an excellent alternative to Onyx™ that allows our customers to save money when using your Markforged printer.

Don’t have a Markforged printer? That’s no problem – Obsidian™ is also compatible with all non-Markforged printers that are suitable for printing PA6+CF.

Take advantage of the excellent strength, stiffness, and appearance of this specialty material without over spending on Markforged Onyx™.

Technical data sheet for this product here

Diameter: 1.75mm +/- 0.05mm

1000g rolls in BLACK only

Obsidian™ was formulated to be a drop-in for Onyx™ without any changes to the print settings.

3DXTech Recommended Print Settings for Non-Markforged Printers:

Formtech's Settings for what I have tweaked for my machines ( Non MF)

Drying Instructions: 90°C for 4 hours if the filament exhibits signs of moisture

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!