Trending searches

Popular products

Cart ($0)

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

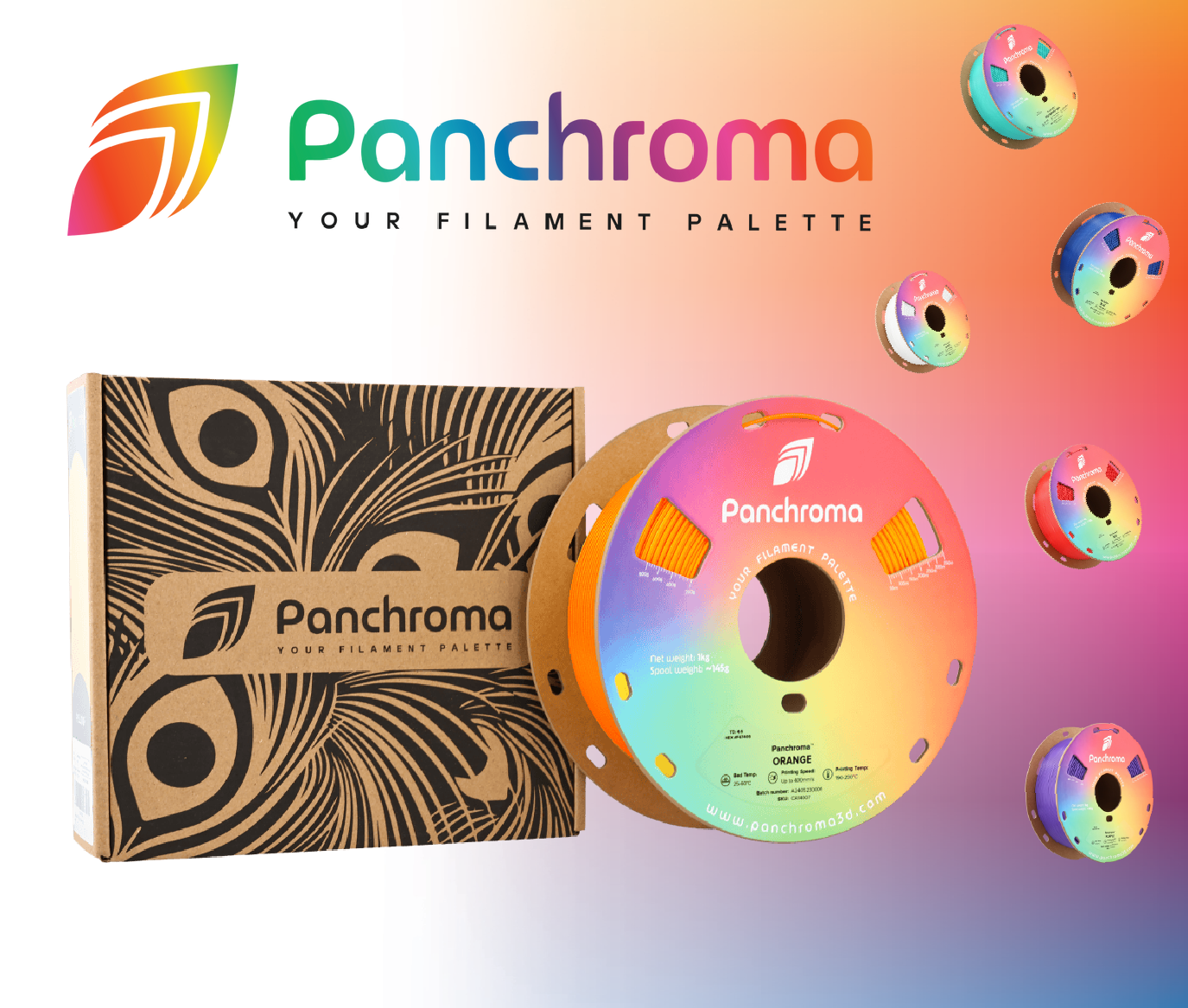

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Want detail in your prints, try resin 3d printing for that fine detail.

Quality brands you can trust

Contract signed directly with Polymaker Factory

Usually ready in 1 hour

Meet our new generation LW-PLA-HT WHITE. This formulation features an increased temperature resistance compared to our generic LW-PLA.

Thin printed structures will be able to handle heat from external sources such as the sun much better and prolong the time until failure. Not convinced? Check out our comparison video in the image gallery between regular LW-PLA and LW-PLA-HT.

Our LW-PLA-HT is the best filament for printing RC Planes, Cosplay and other light weight items. Parts are feather light, yet retain good strength and are easy to cut, trim and sand.

Read our tutorial: Upgrading from LW-PLA to LW-PLA-HT, what you need to know.

Pros

better heat resistance compared to LW-PLA

better heat resistance compared to LW-PLA

print light weight parts due to active foaming process

print light weight parts due to active foaming process

darker colors are less prone to heat deformation

darker colors are less prone to heat deformation

takes paint really well

takes paint really well

Cons slightly higher density at maximum foaming, compared to LW-PLA

slightly higher density at maximum foaming, compared to LW-PLA

you’ll have to adjust your LW-PLA gcodes to accommodate LW-PLA-HT

you’ll have to adjust your LW-PLA gcodes to accommodate LW-PLA-HT

higher temperature resistance of the material can lead to more warping

higher temperature resistance of the material can lead to more warping

Printing Settings:

For printing thin structures such as RC plane parts we recommend printing the first layer at 100% flow using 200C printing temperature. Then increase the temperature for the second layer (around 235C) to activate the foaming and reduce flow to 50-60%.

|

Advised 3D printing temperature 195-240C |

|

Advised 3d print speed 40 - 100 mm/s |

|

Advised Heated bed (if you have one, not strictly necessary): 50-60C |

|

Cooling fan -NIL |

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!