STARTOUT - 3D PRINTER PACKAGE

STARTOUT - 3D PRINTER MULTI COLOUR PACKAGE

CHRISTMAS ENGINEERING 3D PRINTER & GREY PETG PACKAGE

CHRISTMAS ENGINEERING 3D PRINTER & BLACK PETG PACKAGE

CHRISTMAS DEALS

Grab a deal before Santa does....

AZUREFILM - PLA MATTE HIGH SPEED

AZUREFILM HYPERSPEED PETG REFILLS

AZUREFILM HYPERSPEED PETG MASTERSPOOL

AZUREFILM - SILK RAINBOWS

AZUREFILM

Making the impossible possible with Azurefilm....

Carbon Fibre Filaments

Obsidian Markforged filaments

Glass Fibre Reinforced Filaments

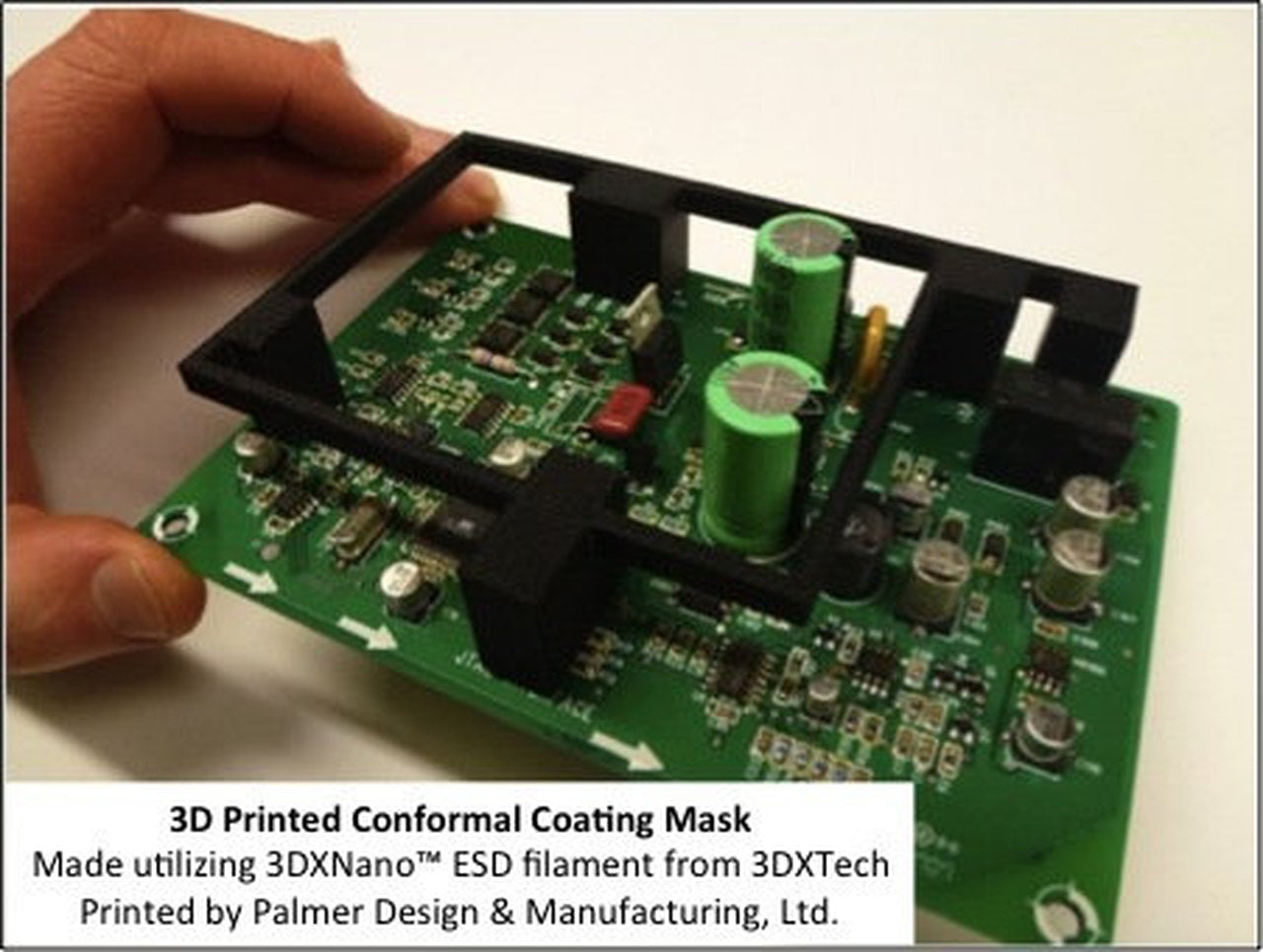

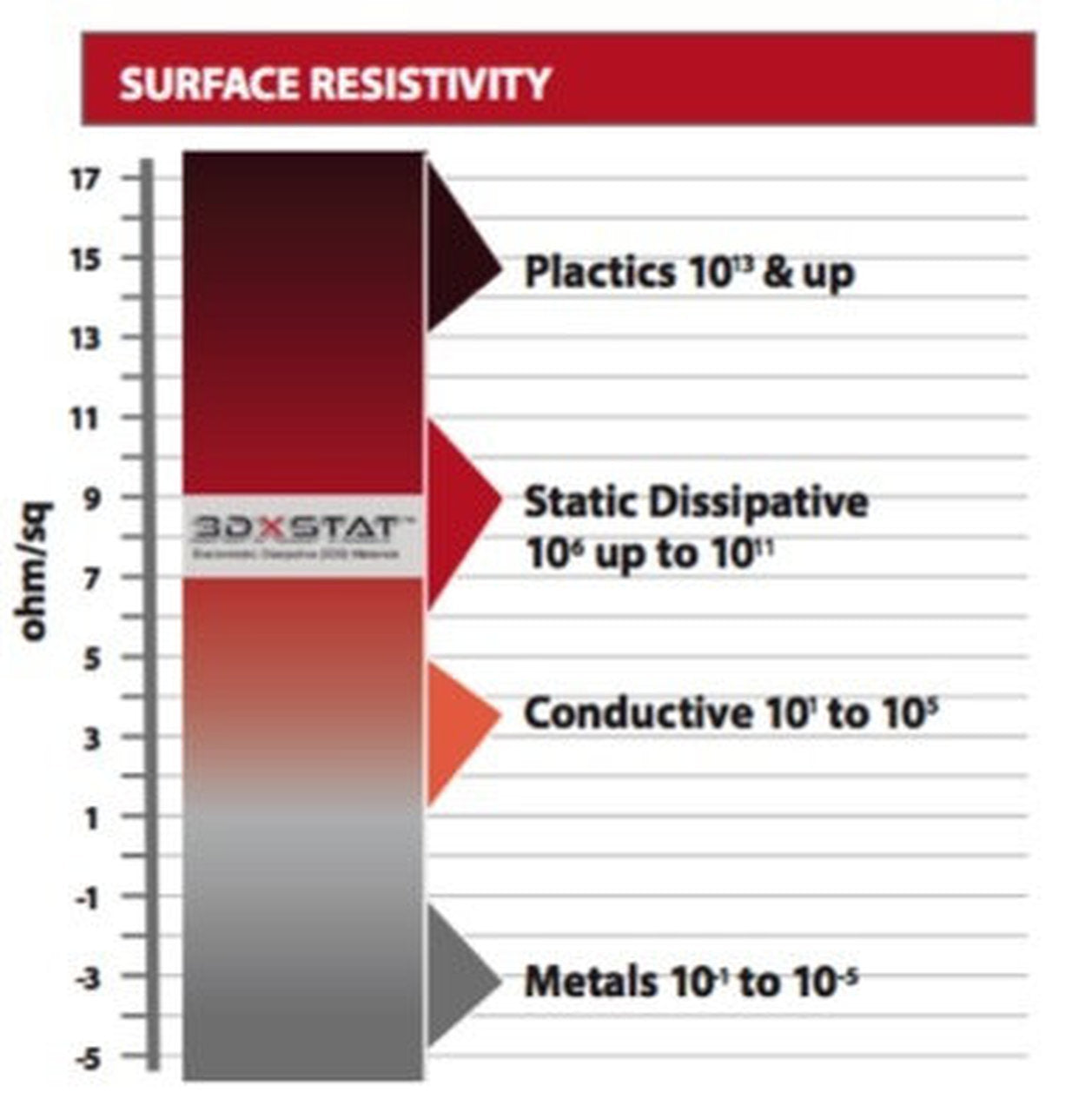

ESD Safe Filaments

Nylon Chemical Resistance

PC Heat Resistance

ASA UV STABLE Exterior

Support Filament

TPU Flexible

SHOP ALL - 3DXTech Printing Filaments

3DXTECH FILAMENTS

Fiberon™ PETG

Fiberon™ PPS

Fiberon™ PA6-CF20 Nylon

Fiberon™ PETG-ESD

Fiberon™ PA6-GF25 Nylon GF

Fiberon™

Master composite materials with Fiberon™

Panchroma™ Basic

Panchroma™ PLA Matte

Panchroma™ PLA Matte Muted

Panchroma™ PLA Satin

Panchroma™ PLA Pastel

Panchroma™ PLA Mable

Panchroma™ PLA Dual

Panchroma™ PLA Gradient

Panchroma™ PLA Galaxy

Panchroma™ PLA StarLight

Panchroma™ PLA Translucent

Panchroma™ PLA Luminous

Panchroma™ PLA Celestial

Panchroma™ PLA Neon

Polymaker HT-PLA

PolyLite™ CosPLA

PolyLite™ LW-PLA

PolyWood™ PLA Wood

PolyLite™ PETG

PolyLite™ ABS/ASA

PolyFlex™ TPU95

PolyCast™ (Casting)

PolyMaker PC

SHOP ALL - Polymaker Filaments

Polymaker

Unleash Your Creativity With Panchroma™

iSANMATE High Speed PLA+ i6

iSANMATE High Speed Matte PLA+

iSANMATE High Speed Multi Colour PLA+

iSANMATE Silk Tri colour PLA+

iSANMATE Matte Gradient PLA+

iSANMATE Rainbow PLA+

iSANMATE Transparent PLA+

iSANMATE Wood PLA+

iSANMATE ABS

iSANMATE ASA Gradient

iSANMATE Carbon

SHOP ALL - iSANMATE HIGH QUALITY FILAMENTS

RAINBOW FILAMENTS

KIWIFIL NZ 1kg Rolls

KIWIFIL NZ 250g Rolls

KIWIFIL NZ 5kg Rolls

SHOP ALL - Kiwifil Filaments

KIWIFIL NZ

Made in New Zealand

PRUSA 3D PRINTERS

QIDITECH 3D PRINTERS

BAMBU LAB 3D PRINTERS

PRODUCTION PRINTERS

AMS UNITS

3D PRINTER BUNDLES

SHOP ALL 3D PRINTERS

3D PRINTING MACHINES

Class leading machines to inspire your creations

BED ADHESION ( GLUES/SPRAYS)

BUILD PLATES/ CRYO BEDS

BAMBOO BUILD PLATES

BIQU BIGTREETECH PARTS

BAMBOO LAB UPGRADES

PHAETUS PRODUCTS

QIDITECH REPLACEMENT PARTS

HOTEND UPGRADES

BOWDEN TUBE AND FITTINGS

PRINTER NOZZLES

REPLACEMENT PARTS

You have no recently viewed items.

3DXTECH USA

POLYMAKER™

iSANMATE

PRUSA RESEARCH

QIDITECH

PHAETUS PRODUCTS

MAGIGOO

KIWIFIL NZ

SLICE ENGINEERING

FORMTECH

CAPRICORN TUBE

E3D ONLINE

BIQU PARTS

Our Brands

Quality brands you can trust

TESTIMONIALS and REVIEWS

3D RESOURCES & DOCUMENTS

GO TRACK PARCEL TRACKING

NEWS AND TIPS

CONTACT US

BUSINESS B2B ACCOUNT

3DXTECH FILAMENTS

iSANMATE RAINBOW FILAMENTS

KIWFIL FILAMENTS

MAGIGOO

SLICE ENGINEERING

CAPRICORN TUBE

E3D ONLINE

iSANMATE PLA + COLOURS RANGE

NEW PRODUCTS

PLA+ & PLA Pro FILAMENTS

rPETG FILAMENTS

PETG FILAMENTS

ABS FILAMENTS

ASA (UV STABLE) FILAMENTS

CARBON FIBRE FILAMENTS

SUPPORT 3D FILAMENTS

ESD-SAFE FILAMENTS

HIGH TEMPERATURE FILAMENTS

Click to open expanded view

3DXSTAT™ESD-Safe PEI 3D Filament ( Non-Conductive) MADE USING ULTEM™ PEI

Sale price

$123.00

Regular price

$143.00

You save

14%

Tax included. Shipping calculated at checkout.

Diameter: 1.75mm 250g Black ( Local NZ Stock)

Only 4 left in stock!

Pickup available at Formtech Christchurch

Usually ready in 2 hours

Share this product

Technical data Sheets

Product Description

3DXSTAT™

ESD-Safe PEI 3D Filament

MADE USING ULTEM™ PEI

Shipment : NOW IN STOCK

3DXTECH produces this 3D printing filament using a specialty compound custom-formulated using ULTEM™ PEI resin and advanced carbon additives.

PEI is an amorphous, high-performance polymer that combines excellent mechanical, thermal, and chemical resistance properties.

Our PEI based filaments offer the ability to create parts with excellent properties at elevated temperatures due to a very high glass transition temperature (Tg).

Ideal for use in critical applications that require electrostatic discharge (ESD) protection, a high level of cleanliness, and the outstanding thermal and chemical properties you've come to expect with PEI based compounds.

3DXTech filaments properties comparison table >> click here <<

PRICE SAVING in bulk - We can do bulk packs in 5 or 10, please email us for a quote

Product attributes include:

- 10^6 to 10^7 ohm surface resistivity on 3DP sample using concentric ring test method

- Consistent surface resistivity

- Low particulate contamination

- High thermal properties

- Inherent flame resistance

- Long-term hydrolytic stability

- Excellent dimensional stability (low creep sensitivity and low, uniform coefficient of thermal expansion) and highly reproducible part-to-part dimensions

- Exceptional strength and modulus, even at elevated temperatures

- Good resistance to a broad range of chemicals, such as automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

- Stable dielectric constant and dissipation factor over a wide range of temperatures and frequencies

Typical applications include:

- Semi-con / Electronics: HDD Components, Wafer Handling, Jigs, Casings, & Connectors

- Industrial: Conveying, Metering, and Sensing applications

Filament Specifications:

- Diameter: 1.75mm (+/- 0.05mm)

Surface conductivity as a function of extruder temperature:

The surface resistance of the printed ESD-safe part will vary depending on the printer's extruder temperature. For example, if your testing indicates the part is too insulative, then increasing the extruder temperature will result in improved conductivity. Therefore, the surface resistance can be 'dialed-in' by adjusting the extruder temperature up or down depending on the reading you receive on your part.

Recommended Print Conditions:

- Extruder Temp: 360 - 390°C (all-metal extruder)

- Bed Temp: 140 - 160°C

- Bed Prep: PEI tape (ideal); or Polyimide Tape, Lightly sanded FR4 or Perf board.

- Other: No cooling fan, Print speeds of 1000mm/min (starting point)

- Drying Instructions: Please see the following instructions for when you want to dry out this filament.

Annealing Printed Parts: If needed, parts printed using PEI may be annealed in a hot-air oven to reduce any printed-in stresses that may be present in the part. Printed-in stresses may occur in any plastic and may result in lower than expected mechanical properties. If this is an issue with your part, then you can follow the simple 5-step ramp up/down process for annealing the PEI parts.

Step 1: Place printed parts in cool, room-temp oven.

Step 2. Set temp to 300°F and allow to stabilize for 1 hour.

Step 3: After 1 hour at 300°F, increase oven temp to 400°F and allow to stabilize 1 additional hour.

Step 4: After 1 hour at 400°F, reduce heat back to 300°F and allow to stabilize for 30 minutes.

Step 5: After 30 minutes, turn off oven heat and allow printed parts to return to room temp inside the oven as it cools.

ULTEM™ is a registered trademark of Sabic Innovative Plastics.

3DXTECH manufactures this filament using a custom-formulated ESD-safe compound made using ULTEM™ PEI resin.

Recommended for You

- Choosing a selection results in a full page refresh.

Serious Stuff:

Quick Browse:

Our mission:

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

Follow us on:

!

![iSANMATE High-Speed PLA 3D Printer Filament Rainbow 03 [Fairy Floss] 1kg roll](http://www.formtech.co.nz/cdn/shop/files/High-speed-PLA-Rainbow-1-600x600_70x.jpg?v=1713148368)

![iSANMATE High-Speed PLA 3D Printer Filament Rainbow 01 [Lollipop] 1kg roll](http://www.formtech.co.nz/cdn/shop/files/High-speed-PLA-Rainbow-01-1-600x600_70x.jpg?v=1713147615)