Trending searches

Popular products

Cart ($0)

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Want detail in your prints, try resin 3d printing for that fine detail.

Quality brands you can trust

Usually ready in 1 hour

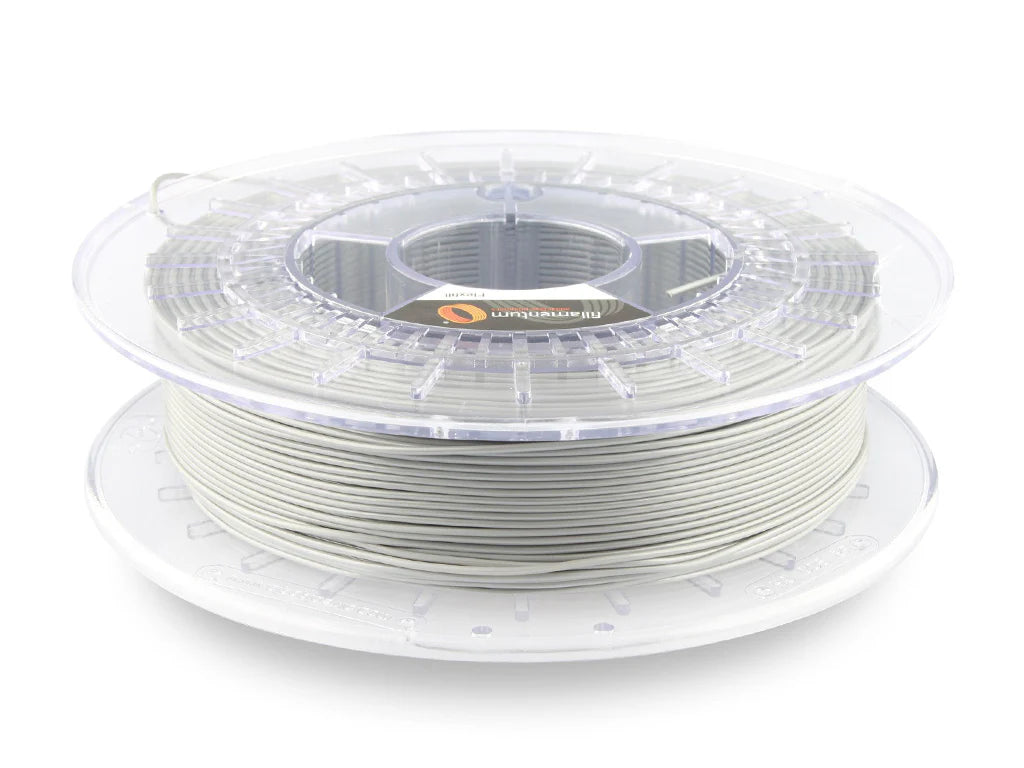

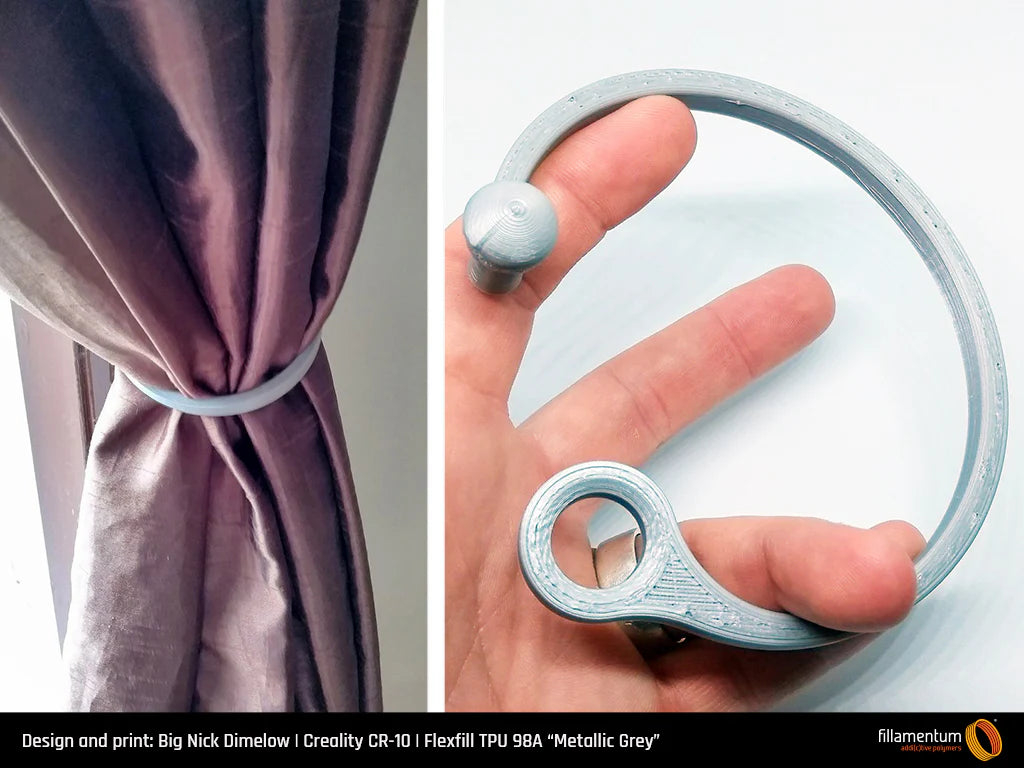

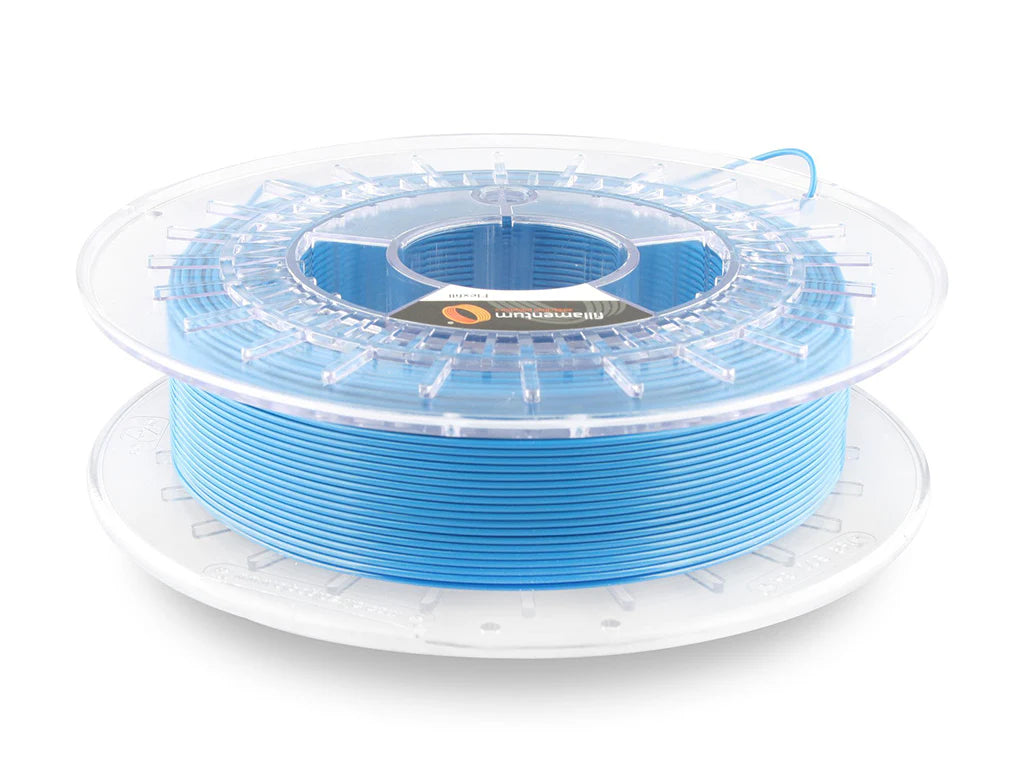

Thermoplastic polyurethane with hardness 98 Shore A. A technical semi-flexible filament that offers great mechanical properties such as high tear and tensile strength.

It is characterized by highly reversible deformation, resistance to ozone, oils, greases, and aliphatic alcohols. Wear resistance guarantees the durability of 3D printed products. Great for the printing of continually sliding parts or sealings.

Features:

Printing Temperature: 220 – 240 °C

Printing Temperature: 220 – 240 °C

Bed Temperature: 50 – 60 °C

Bed Temperature: 50 – 60 °C

Printing Speed: 15 – 30 mm/s

Printing Speed: 15 – 30 mm/s

Cooling Fan: 70- 100 %

Cooling Fan: 70- 100 %

Downloads:

Tech Specs: https://drive.google.com/file/d/16nWfofBg8NAJmiAH4TzWvvf4W56hqiRb/view?usp=drive_link

| Flexfill TPU | Flexfill TPE | Flexfill PEBA | |

|---|---|---|---|

| Polymer base: | Polyurethane + ester | Polyolefin + SEBS | Polyamide + ether |

| Tensile strength: | 49 MPa | 5 MPa | 36 MPa |

| Elongation at break: | 600 % | 250 % | > 1000 % |

| Density: | 1.20 g/cm³ | 1.15 g/cm³ | 1.00 g/cm³ |

| Sensitivity to moisture: | High | Low | High |

| Chemical resistance: | Oils, greases, ozone | Water, acids, alcohols, alkalis | Car fluids, toluene, acetone, ozone |

| Food & skin contact: | Not recommended | Certificated | Not certificated |

| Gas permeability: | High | Low | Medium |

| Optical properties: | Glossy, transparent | Matte, non-translucent | Glossy, very transparent |

| For example, ideal for applications: | |||

| Vibration: | Anti-vibration, damping | Anti-vibration, damping | Vibration and energy transfer |

| Skin contact: | – | Long-term touch of human skin (holding in hands) | – |

| Under temperature: | +80–100 °C | +80 °C | -40 °C |

| In contact with: | oils | water | car fluids |

| Abrasion: | Sliding abrasion | – | Impingement abrasion |

| Other: | – | Outdoor | Low density |

| Other: | – | – | Rebounding |

Thermoplastic polyurethane with hardness 98 Shore A. A technical semi-flexible filament that offers great mechanical properties such as high tear and tensile strength.

It is characterized by highly reversible deformation, resistance to ozone, oils, greases, and aliphatic alcohols. Wear resistance guarantees the durability of 3D printed products. Great for the printing of continually sliding parts or sealings.

Features:

Printing Temperature: 220 – 240 °C

Printing Temperature: 220 – 240 °C

Bed Temperature: 50 – 60 °C

Bed Temperature: 50 – 60 °C

Printing Speed: 15 – 30 mm/s

Printing Speed: 15 – 30 mm/s

Cooling Fan: 70- 100 %

Cooling Fan: 70- 100 %

Downloads:

Tech Specs: https://drive.google.com/file/d/16nWfofBg8NAJmiAH4TzWvvf4W56hqiRb/view?usp=drive_link

| Flexfill TPU | Flexfill TPE | Flexfill PEBA | |

|---|---|---|---|

| Polymer base: | Polyurethane + ester | Polyolefin + SEBS | Polyamide + ether |

| Tensile strength: | 49 MPa | 5 MPa | 36 MPa |

| Elongation at break: | 600 % | 250 % | > 1000 % |

| Density: | 1.20 g/cm³ | 1.15 g/cm³ | 1.00 g/cm³ |

| Sensitivity to moisture: | High | Low | High |

| Chemical resistance: | Oils, greases, ozone | Water, acids, alcohols, alkalis | Car fluids, toluene, acetone, ozone |

| Food & skin contact: | Not recommended | Certificated | Not certificated |

| Gas permeability: | High | Low | Medium |

| Optical properties: | Glossy, transparent | Matte, non-translucent | Glossy, very transparent |

| For example, ideal for applications: | |||

| Vibration: | Anti-vibration, damping | Anti-vibration, damping | Vibration and energy transfer |

| Skin contact: | – | Long-term touch of human skin (holding in hands) | – |

| Under temperature: | +80–100 °C | +80 °C | -40 °C |

| In contact with: | oils | water | car fluids |

| Abrasion: | Sliding abrasion | – | Impingement abrasion |

| Other: | – | Outdoor | Low density |

| Other: | – | – | Rebounding |

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!