Trending searches

Popular products

Cart ($0)

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Want detail in your prints, try resin 3d printing for that fine detail.

Quality brands you can trust

Usually ready in 1 hour

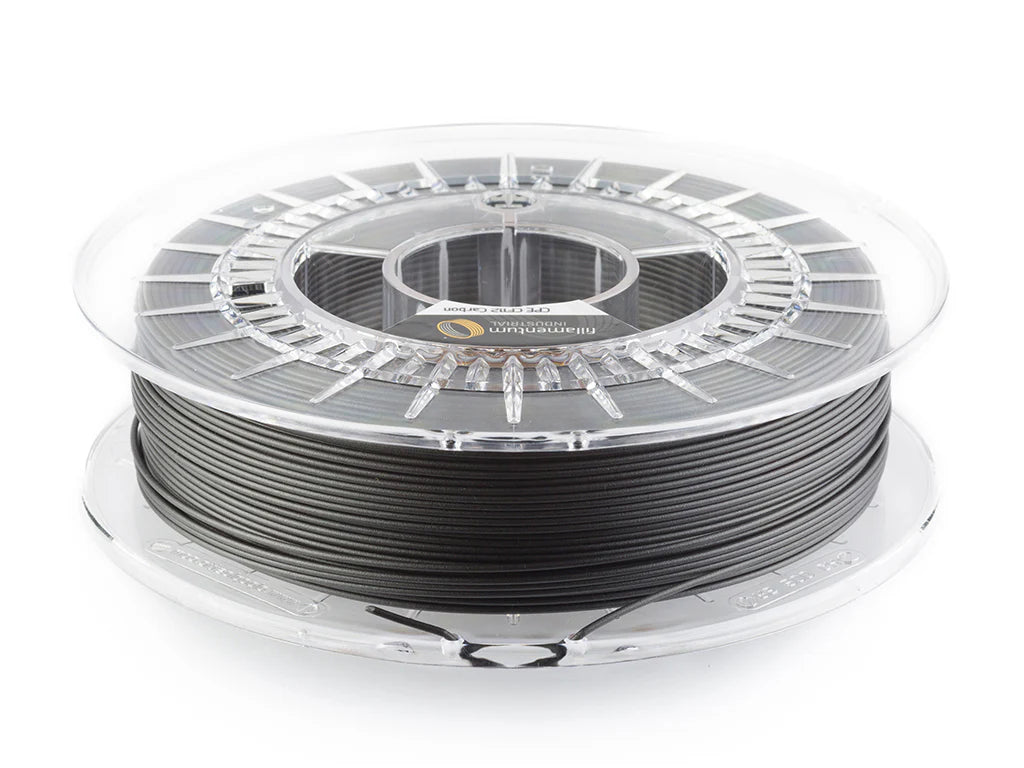

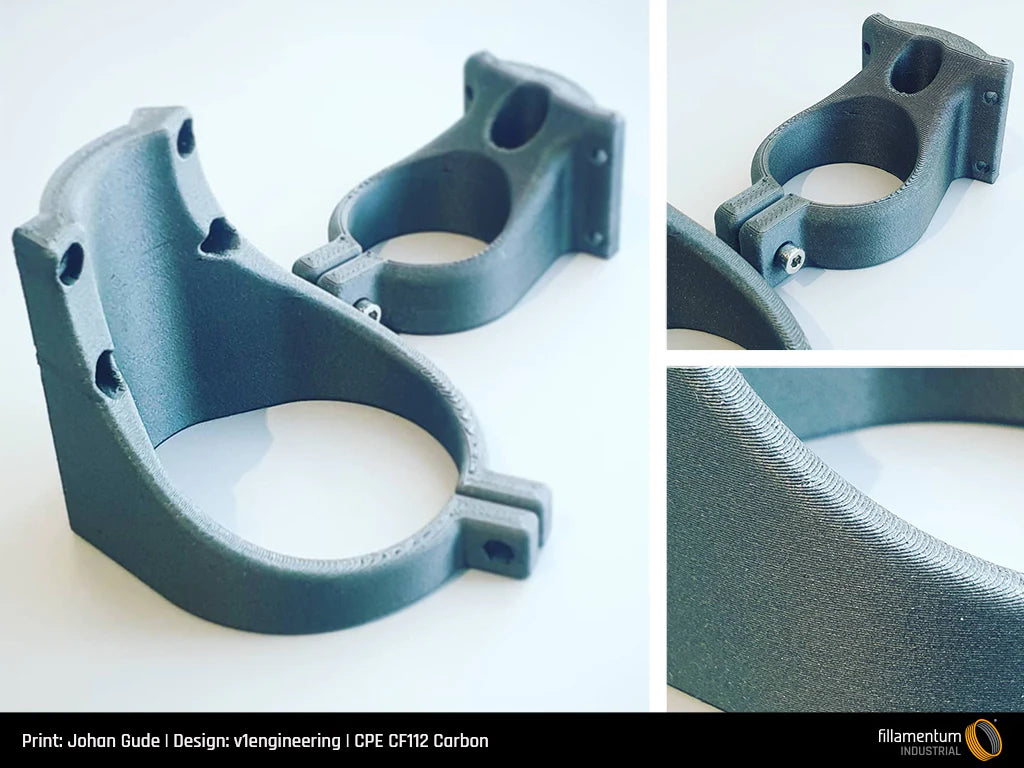

This advanced filament combines carbon fibers with CPE HG100 for superior durability, printability, and dimensional stability.

It offers excellent pressure resistance, hardness, and a smooth matte finish, making it ideal for applications under long-term loads.

Compared to standard CPE HG100, it delivers enhanced wear resistance, higher heat distortion temperature, and greater chemical resistance.

Features:

Printing Temperature: 250 – 270 °C

Printing Temperature: 250 – 270 °C

Bed Temperature: 70 – 85 °C

Bed Temperature: 70 – 85 °C

Printing Speed: 30 – 50 mm/s

Printing Speed: 30 – 50 mm/s

Cooling Fan: 0 – 15 %

Cooling Fan: 0 – 15 %

Downloads:

Tech Specs: https://drive.google.com/file/d/16nWfofBg8NAJmiAH4TzWvvf4W56hqiRb/view?usp=drive_link

| CPE CF112 Carbon | CPE HG100 | PETG | |

| Impact resistance | 106 kJ/m² (unnotched) | 258 kJ/m² (unnotched) | 237 kJ/m² (unnotched) |

| Tensile strength | 52 MPa | 48 MPa | 50 MPa |

| Elongation at break | 8% | 150% | 120% |

| Hardness | 94 R-Scale | 115 R-Scale | 105 R-Scale |

| 77 Shore D | 75 Shore D | 75 Shore D | |

| Flexural strength | / | 71 MPa | 71 MPa |

| Flexural modulus | / | 1860 MPa | 2150 MPa |

| Wear resistance | «««« | «« | « |

| Creep resistance | «««« | «« | « |

| Heat resistance (HDT) | up to 100 °C | 80 °C | 70 °C |

| Chemical resistance to acids, bases, hydrocarbons | good | good | poor |

This advanced filament combines carbon fibers with CPE HG100 for superior durability, printability, and dimensional stability.

It offers excellent pressure resistance, hardness, and a smooth matte finish, making it ideal for applications under long-term loads.

Compared to standard CPE HG100, it delivers enhanced wear resistance, higher heat distortion temperature, and greater chemical resistance.

Features:

Printing Temperature: 250 – 270 °C

Printing Temperature: 250 – 270 °C

Bed Temperature: 70 – 85 °C

Bed Temperature: 70 – 85 °C

Printing Speed: 30 – 50 mm/s

Printing Speed: 30 – 50 mm/s

Cooling Fan: 0 – 15 %

Cooling Fan: 0 – 15 %

Downloads:

Tech Specs: https://drive.google.com/file/d/16nWfofBg8NAJmiAH4TzWvvf4W56hqiRb/view?usp=drive_link

| CPE CF112 Carbon | CPE HG100 | PETG | |

| Impact resistance | 106 kJ/m² (unnotched) | 258 kJ/m² (unnotched) | 237 kJ/m² (unnotched) |

| Tensile strength | 52 MPa | 48 MPa | 50 MPa |

| Elongation at break | 8% | 150% | 120% |

| Hardness | 94 R-Scale | 115 R-Scale | 105 R-Scale |

| 77 Shore D | 75 Shore D | 75 Shore D | |

| Flexural strength | / | 71 MPa | 71 MPa |

| Flexural modulus | / | 1860 MPa | 2150 MPa |

| Wear resistance | «««« | «« | « |

| Creep resistance | «««« | «« | « |

| Heat resistance (HDT) | up to 100 °C | 80 °C | 70 °C |

| Chemical resistance to acids, bases, hydrocarbons | good | good | poor |

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!