Extruder Temp: 210-240°C

Bed Temp : 23-60°C

Heated Chamber: Not required

Nozzle Specs: No special concerns

Bed Adhesion: Magigoo Bed Prep

Layer Height: No special concerns

Drying Specs: 65°C for 4 hours

Benefits of PLA Include:

Cart ($0)

Grab a deal before Santa does....

Making the impossible possible with Azurefilm....

Master composite materials with Fiberon™

Unleash Your Creativity With Panchroma™

Made in New Zealand

Class leading machines to inspire your creations

Quality brands you can trust

Usually ready in 24 hours

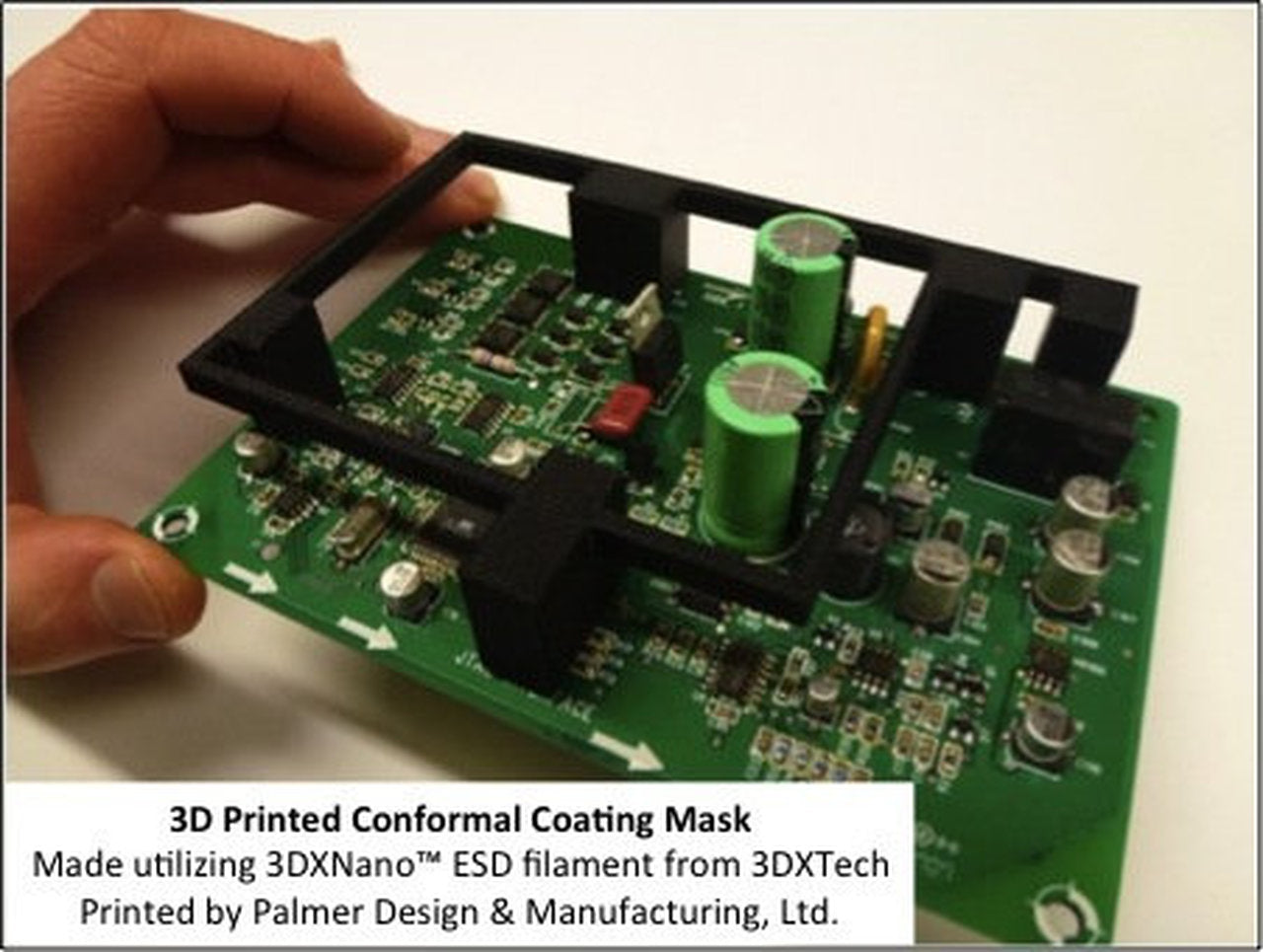

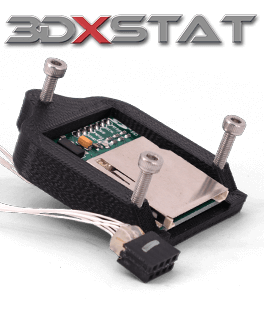

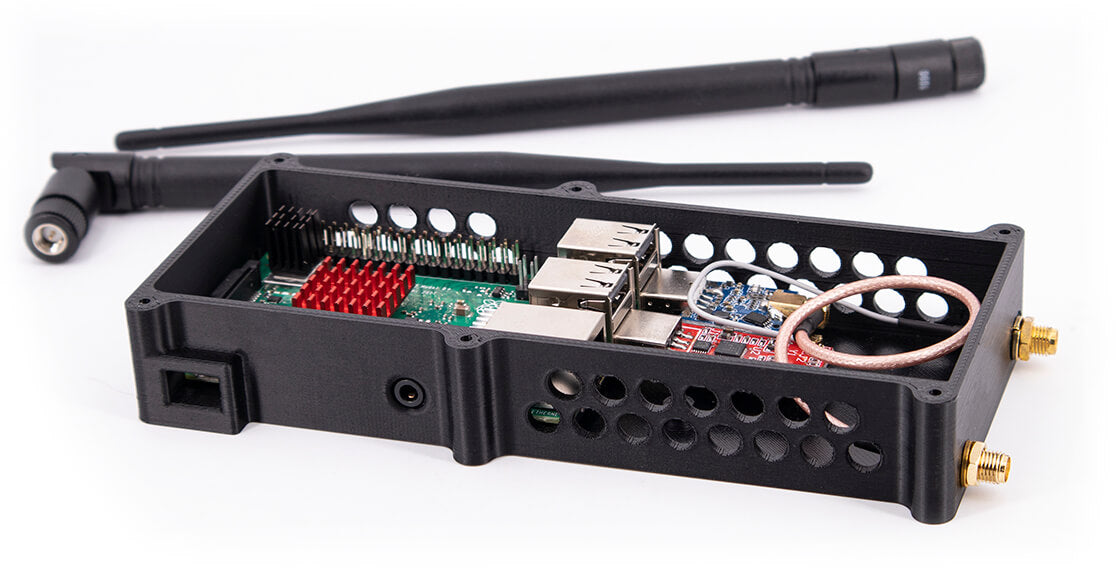

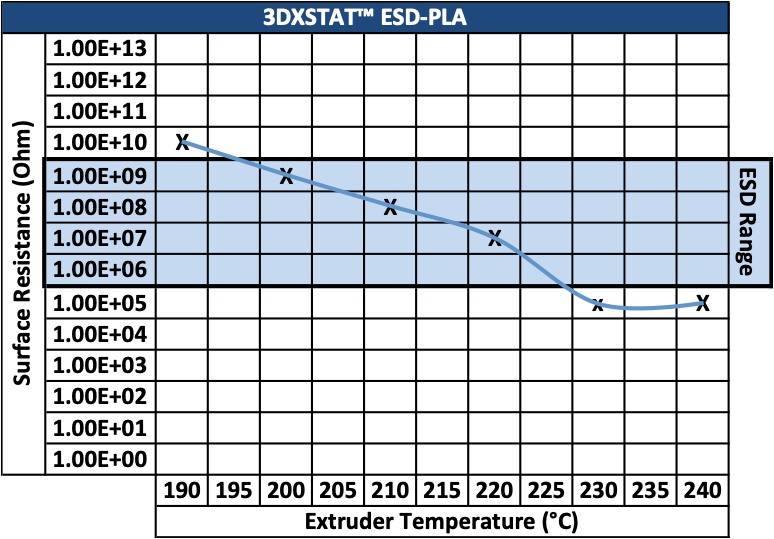

3DXSTAT™ ESD PLA is an advanced ESD-Safe compound designed for use in critical applications which require electrostatic discharge (ESD) protection. Made using cutting-edge multi-wall carbon nanotube technology, state of the art compounding technology, and precision extrusion processes. Target surface resistance: 10^7 to 10^9 Ohm.

Extruder Temp: 210-240°C

Bed Temp : 23-60°C

Heated Chamber: Not required

Nozzle Specs: No special concerns

Bed Adhesion: Magigoo Bed Prep

Layer Height: No special concerns

Drying Specs: 65°C for 4 hours

Benefits of PLA Include:

The surface resistance of the printed ESD PLA part will vary depending on the printer’s extruder temperature. For example, if your testing indicates the part is too insulative, then increasing the extruder temperature will result in improved conductivity. Therefore, the surface resistance can be ‘dialed-in’ by adjusting the extruder temperature up or down depending on the reading you receive on your part.

1.75mm and 2.85mm +/- 0.05mm in diameter

Formtech was founded to provide high-quality 3D printing materials to both businesses and individuals.

We are committed to supporting the growth of 3D printing in New Zealand and Australia.

!